Anycubic i3 Mega S Extruder Conversion

With the original extruder it was not possible to print small circles without problems. If you had to print a plate with many small holes, there were always problems. This was caused by the original Bowden extruder. We explained the difference between a Direct Extruder compared to the Bowden Extruder in the 3D Printer Tutorial. After a retract (filament retraction), the filament to be extruded always came out of the nozzle too late with the Bowden extruder.

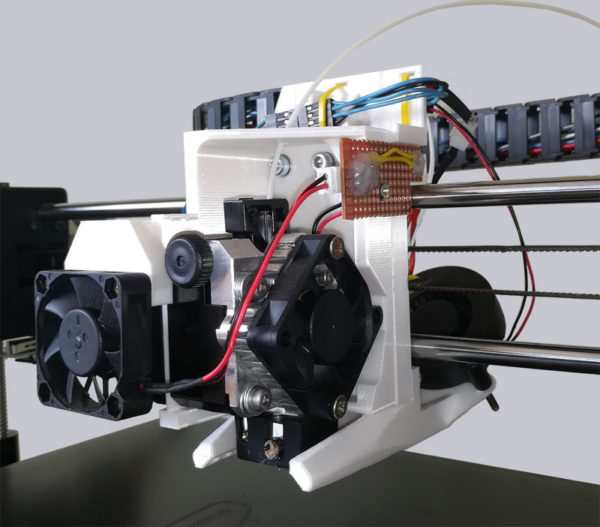

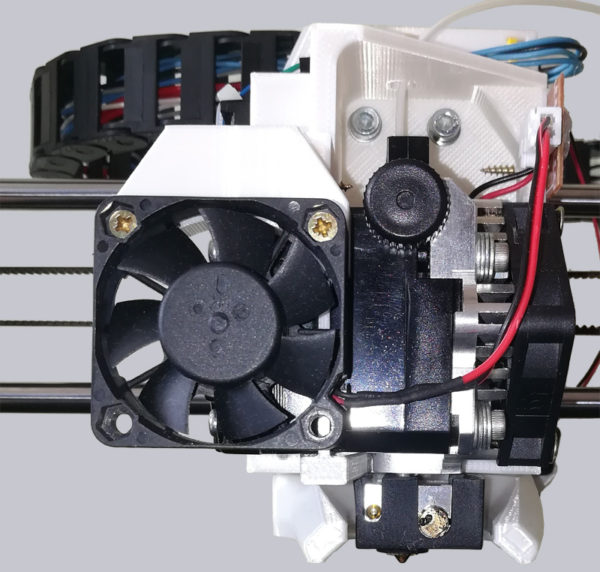

That’s why we’ve installed a direct extruder – namely the Titan Aero Extruder.

The drastically reduced distance from the extruder drive to the die tip allows a much more precise retraction and restart of conveying than with a Bowden extruder.

The Titan Aero is sold as a complete kit including a V6 full metal hot end and stepper motor. Heating element, thermal sensor and the hotend fan are included, as well as a silicone sock for the heating block. This protects the heating block from cooling air so that even if the speed of the component fan fluctuates, the temperature at the nozzle remains as constant as possible. Likewise, the silicone sleeve protects the surrounding parts from heat exposure.

However, we immediately replaced the supplied stainless steel heatbreak with a titanium heatbreak. Although various 3D printer forums advise against using a titanium heatbreak when printing PLA filament, our personal experience has been excellent with this interaction.

The X-slide as well as the extruder holder mounted on it are a completely custom design. We also added an additional 40mm fan in front of the extruder’s stepper motor to keep the motor as cool as possible. This is because we want to keep the heat input into the design as low as possible. Even at higher printing speeds, the motor stays cool well below 40°C.

Finally, we even replaced the stepper motor of the Titan Aero extruder with an even shorter model, thus reducing the moving mass significantly. Performance-wise, this is no problem. The motor even gets along with 0.5V reference voltage at the TMC2208 motor driver.

The fans of the hotend and the stepper motor are connected together on a small PCB. These are supplied by a single voltage source. Thus we have only one line for both fans in the cable tow.

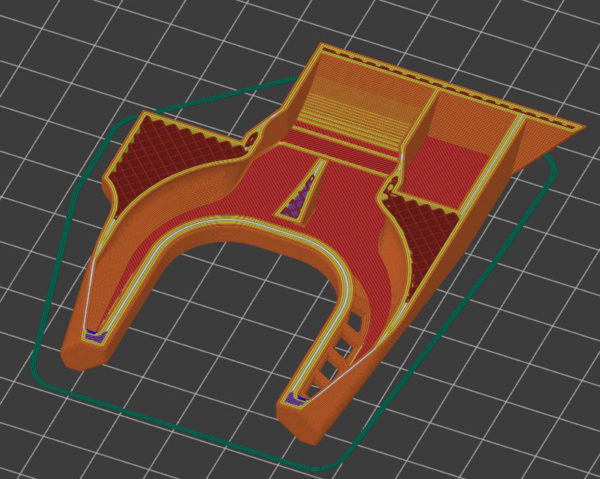

When designing all components, we paid particular attention to good printability and mountability, as we were not very satisfied with the designs found on various platforms in this regard. Even if there are highly praised designs on the Internet and on relevant YouTube channels, everyone collects their own experiences.

Continuing with the optimization of the Anycubic i3 Mega S cabling …