What does an FDM 3D Printer consist of?

The heart of the 3D printer is the Extruder. In the extruder, the filament is heated to approx. 170 – 300 °C with a heating element, depending on the type, which almost melts it. The plastic softened by the heating is then pressed out through the nozzle under pressure.

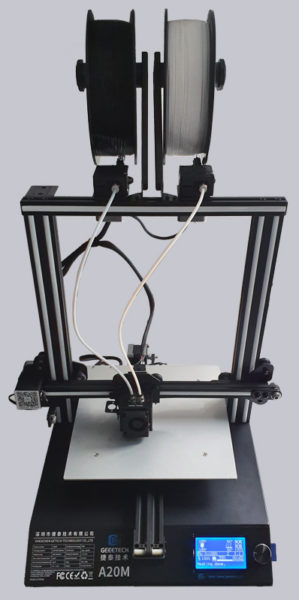

Somewhat more expensive 3D printers often have a Strong dual extruder or Strong dual extruder. This allows you to create 2-color objects without having to use a brush afterwards. An entry model with mixed color printing via a 2in1 extruder hotend is for example the Geeetech A20M 3D printer, (which is even available as Geeetech A20T with 3in1 extruder).

There are basically two types of extruders …

In a direct extruder the drive that pushes the filament through the nozzle is located directly at the print head. This type of extruder is well suited for highly flexible, rubber-like filament types such as TPU. The disadvantage is that the print head is heavy and therefore cannot be operated so dynamically.

The most common type is the so-called Bowden-Extruder. In this variant, the drive for the filament is usually located on the side of the Z-axis and pushes the filament through approx. 30-40cm of Teflon tubing. This keeps the weight of the print head low. Most filament types can be printed without problems with a Bowden extruder.

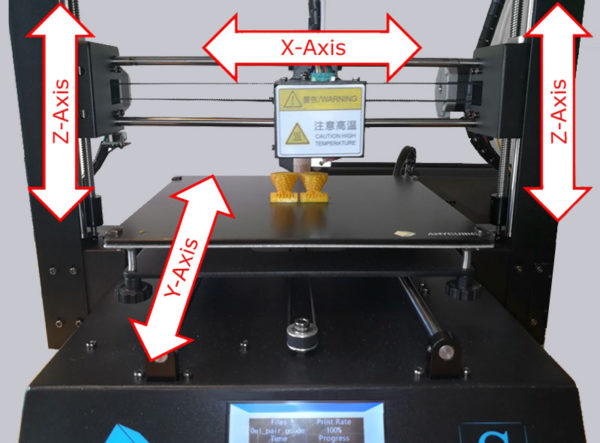

The kinematics usually consists of 3 linear axes (X-, Y- and Z-axis), whereby the bed is usually located on one of the 3 axes and the extruder moves in the other two axis directions.

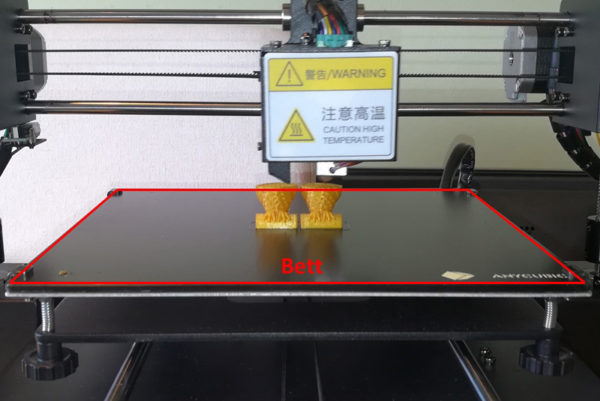

The print object is built up in layers on the bed, also called base.

Often the bed is also heated so that the print object adheres better to it and does not come off early. Filament types that require a particularly high printing temperature also require a heated bed so that the component does not cool down too much during printing.

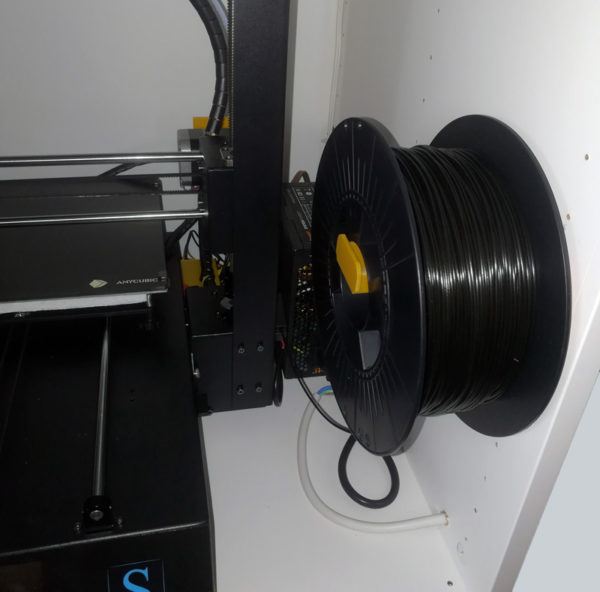

The filament is the raw material for FDM 3D printing. It comes in spools of various sizes and is usually placed on a holder next to the 3D printer where it can easily unwind.

In home use, PLA filament is mostly used for parts without special requirements. It is a product of natural origin and does not emit toxic fumes during printing. It is also very easy to process and has a low price. Even absolute beginners usually achieve a good result with the first print. Other printing materials are available for certain applications, but they require a basic knowledge of 3D printing.

To ensure that the freshly extruded filament solidifies quickly and retains its shape, a component fan is usually installed next to the extruder to cool the growing print object. When the model is finished printing, the 3D printer turns off the heating elements to allow the component to cool down completely. The control of the axes and extruder, as well as temperature control, is usually handled by a minicomputer built into the 3D printer. Some devices can also be fully controlled by an external computer. However, beginners will find a 3D printer with built-in controls faster.

Here’s what you need for 3D printing at home …