Heat conductivities of various materials …

| Copper (IHS + radiator) | up to 400 W/(m.K) |

| Aluminium (cooler/cooling fins) | up to 235 W/(m.K) |

| Nickel (Coating for IHS + Cooler) | 91 W/(m.K) |

| Liquid metal | approx. 70 W/(m.K) |

| high-quality heat conducting paste | 7-12 W/(m.K) |

| Water | 0.556 W/(m.K) |

| Air | 0.026 W/(m.K) |

From the table above, it is easy to see that air between the IHS and the cooler is an insulator and extremely interferes with heat transfer. But even a good thermal paste has only 2-3% of the thermal conductivity of pure copper.

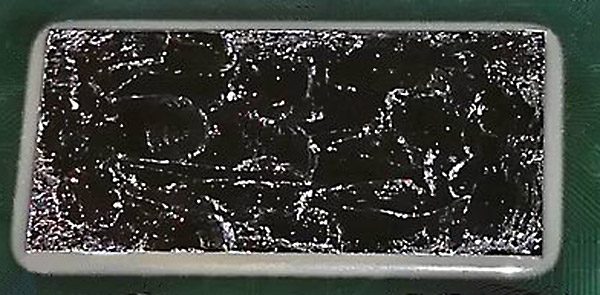

Therefore overclocking enthusiasts try to perfectly grind and polish the contact surface of the IHS and CPU cooler. This should eliminate even microscopic cavities and optimize heat transfer from the CPU to the cooler. This keeps the CPU cooler while maintaining the same performance and generates additional overclocking potential.

Next step, IHS grinding and lapping …