CPU IHS grinding and IHS polishing …

Basically, the idea of lapping the IHS of a CPU is a good approach. In most cases, however, the supposed upgrade does not lead to a noticeable reduction in the CPU temperature, although in the course of grinding and polishing (technically speaking, it is always a grinding), supposed unevenness was eliminated and the surface finally has a high-gloss finish. In the rarest cases the CPU temperature improves after the elaborate procedure by 2°C at best.

Instructions on how to plane and polish the IHS by hand can be found on the Internet. Many also show in the course of the individual work steps how alleged cavities are equalized. Of course we at OCinside.de belong to this genus as well. Therefore we did not spare any efforts for this workshop and also ground and polished a CPU.

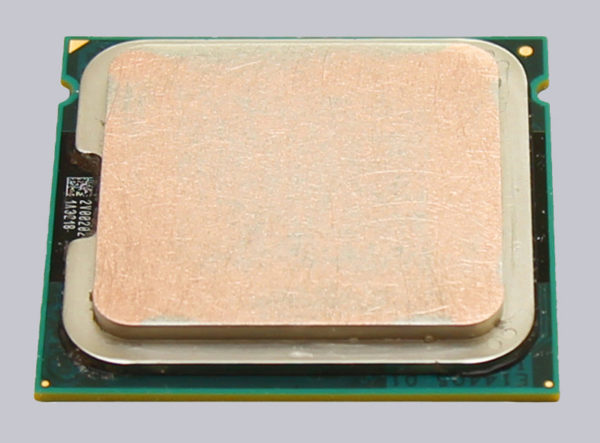

The Intel Core 2 Duo E7500 CPU we used as an example is not a very current model, but its structure is almost identical to the Intel CPU Core i7 8700K, which is extremely popular with gamers and overclockers. Already the rough first polish, where the nickel layer is removed by the heatspreader, shows that our specimen is quite flat and the removal of the nickel layer on the IHS surface is very even.

Here you can see a picture of the roughly ground CPU.

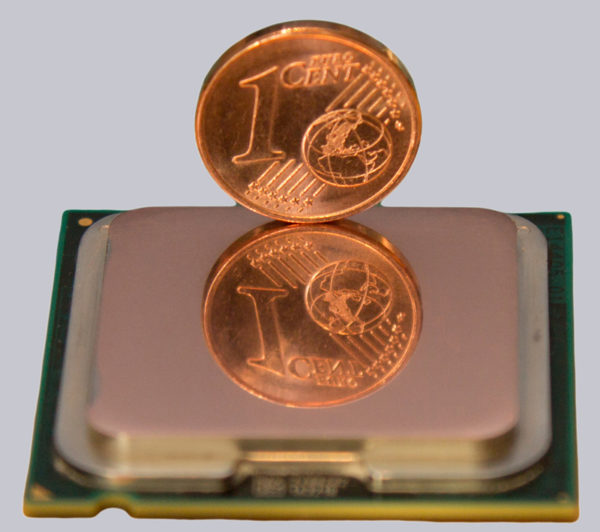

Not every CPU shows such a uniform nickel layer thickness over the entire IHS surface as our test copy. After a few more sanding passes with finer and finer sandpaper up to grain 2400 and subsequent polishing, we have already prepared the IHS surface quite well. At least the mirror factor is very respectable and the surface is so smooth that it can no longer be wetted with water, because it simply rolls off.

The following picture shows the surface quality achieved by us. The picture is of course not a fake, but a real photo!

And how smooth is the IHS really?